Procedure Summary

Machining Considerations

Preparation

Tooling

Mill Geometry

Setting up a machining process

Volume Mill

Local Mill

Trajectory Milling

Holemaking

Engraving

Process Manager

Tool Movement Simulation

Post Processing

CNC Procedure Sheet

CNC Machining Tool Parameters

3d Machining

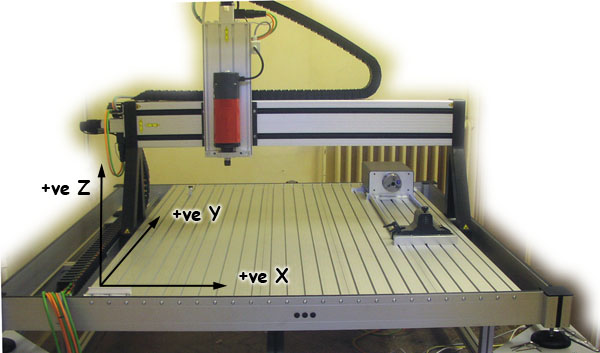

Unimatic Router

ProPlastic Advisor

Unimatic Router - 4 Axis

Movement: X 1000mm Y 1200mm Z 240mm Linear

Max material size is dependent on cutter dimension with the above axis travel limits.

** Your material height [including base board] must not exceed 120mm **

Rotary 4th axis capacity: 160mm dia. x 600mm length

Max feedrate: 4m/min

Roughing Cutter

20mm dia. flat bottomed

1500mm/min horizontal feed

500mm/min plunge feed

10,000 rpm spindle speed

5mm step depth

Finishing cutters - ball nose

3000mm/min horizontal feed

500mm/min plunge feed

16,000 rpm spindle speed

Distance X dictates the maximum depth of cut - approx 110mm

Distance Y has to accommodate the fixing plinth for the job, the thickness of the workpiece and the tool clearance height.

Tool Clearance

To get maximum depth of cut we can use long series cutters or an extension arbor as pictured above.

Which ever method we use, the 25mm dia. clamping nut will need to be considered for side wall clearance when using cutters less than 25mm dia.

Material Clamping

Consider clamping setup *here*

Minimum 10mm thick MDF for base board.

7mm dia. holes drilled at suitable centres in 50mm increments.

Make sure there is adequate cutter clearance around workpiece to baseboard securing screws.

* IMPORTANT * - make the wood screws you use to secure the workpiece onto the base board do not protrude into areas which will be machined - this will scrap the router cutter.

SK20 Collet